Block House / Log House

Block House / Log House in general

Block Houses are massive wooden houses built either with natural trunks or logs (by industrial processing). The walls of such houses, are created by the systematic stacking of wood. The corner joints of walls are made by elaborate connections of individual trunks.

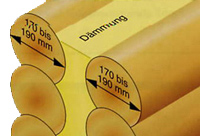

Round planks

Round beams are industrially produced logs which, by the uniform machining process, do not converge on a crest like the natural trunks, but they maintain the same diameter of the entire length of the timber. This guarantees a straight arrangement of the trunks.

Square planks

Square beams are industrially manufactured logs which, unlike round planks, are trimmed on all four sides. As a rule, tongues and grooves are created on the upper and lower sides of the square beam for blocking reason.

Natural Log Houses

As the name suggests, natural logs are kept as "natural" as possible, so trunks remain not processed. Logs are freed from bark only and straightened with an axe or chainsaw so that they can be stacked on top of each other and thus ensure wind protection of the walls. During the full process, logs are not affected by any other industrial work.

Construction

Profile beam

Wooden log houses are produced in several ways. The basic difference between the individual versions is that the walls have different beam profiles. Beam profiles are round or square and can consist of natural logs or log planks (= profiled beams). Examples of the different beam profiles:

Joint types

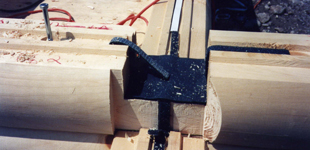

In the production of log houses, a distinction is made between two types of connection, the beam connection (also known as longitudinal joint) and the corner joint.

Beam connections

The planks are stacked lengthwise on top of each other and fastened with nails, screws and threaded rods. This creates a solid connection between the beams

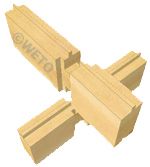

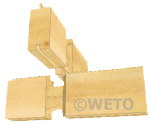

Corner joints

With this type of connection, the individual beams at the corner are cut together to counteract the pressure and tensile loads caused by external forces. In this case, precise processing of the wood is necessary in order to ensure wind protection.

Examples of corner joints created with Viskon log house module

Construction

The single-layer construction

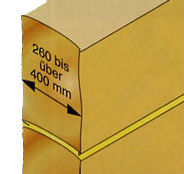

With single-layer log house systems, the log house wall is visible inside and outside and there is no additional insulation. To achieve performing thermal insulation values, wood thicknesses should be within 200 mm and 500 mm.

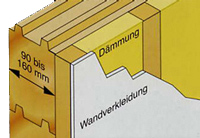

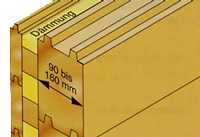

The multi-layer construction

In case of multiple-layer log house systems, there are various design options. However, the approach is always the same. In order to achieve a better thermal insulation value, 2 visible layers are created and in the middle, between them, an insulation layer will be added. With this construction method, wind protection and thermal insulation is therefore easier and better to guarantee than with a single-layer only.